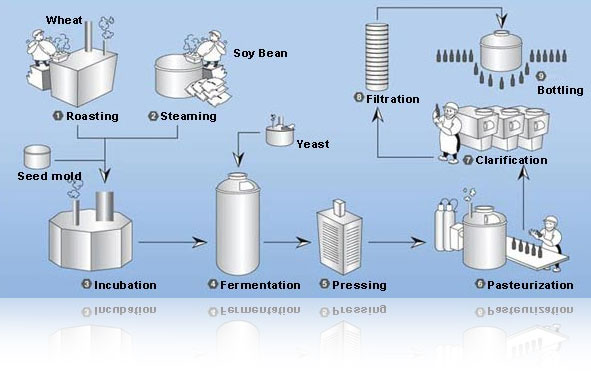

Wheat manufacturing process involves a series of stages. The first stage involves grading of the wheat. In this stage, wheat is received at the flour mill where it is inspected. Samples of wheat are taken for both physical and chemical analysis. In this process, wheat is graded based on some factors but the most important factor is the protein content. The wheat is then kept into silos waiting to be milled. Before the wheat is milled, it has to undergo cleaning process. Wheat is passed through different cleaning processes to remove any foreign materials. The wheat and other small particles are passed through screens.

The wheat is then washed in warm water. Any foreign materials that remained during the cleaning process are removed in this stage. The next step involved in wheat manufacturing process is conditioning. In this process, the wheat is soaked in cold water for about 3 days or at a temperature of 46 degrees Celsius.

Wheat is then grinded where it also undergoes various processes. After that, the wheat is then processed into flour. During processing, small amounts of bleaching agents are added to the flour after milling. The flour is then packed into various bags.

The wheat is then passed through an aspirator which is a device like a vacuum cleaner. The aspirator will suck up any foreign materials that are lighter than the wheat. The wheat is then washed in warm water and air dried. The next step involved in wheat flour production process is conditioning. In this process, the wheat is soaked in cold water for about 3 to 4 days or at a temperature of 46 degrees Celsius.

The wheat is then passed through an aspirator which is a device like a vacuum cleaner. The aspirator will suck up any foreign materials that are lighter than the wheat. The wheat is then washed in warm water and air dried. The next step involved in wheat flour production process is conditioning. In this process, the wheat is soaked in cold water for about 3 to 4 days or at a temperature of 46 degrees Celsius. Wheat flour processing involves various stages. Before the wheat is processed, it must first have to be cleaned. Magnets are used to remove any metallic object, stones, and any other foreign materials that can be attracted by a magnet. Dust and chuffs in the wheat is removed by passing the wheat through air currents. There is an advanced color sorter being used today that separates impurities from the wheat by difference in color. This therefore reduces the product’s overall waste and improves the quality of flour.

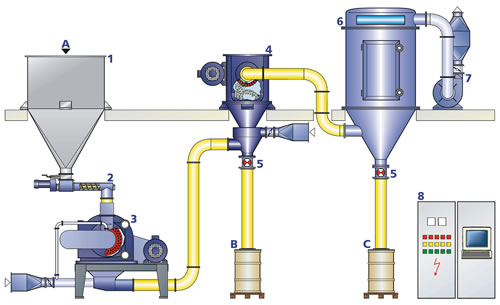

Wheat flour processing involves various stages. Before the wheat is processed, it must first have to be cleaned. Magnets are used to remove any metallic object, stones, and any other foreign materials that can be attracted by a magnet. Dust and chuffs in the wheat is removed by passing the wheat through air currents. There is an advanced color sorter being used today that separates impurities from the wheat by difference in color. This therefore reduces the product’s overall waste and improves the quality of flour. Wheat flour making machine uses a pneumatic roller mill and a high square sifter in making wheat flour. It also has an advanced impulse dust collector which ensures that the workshop is kept clean. This machine is easy to assemble and use. In addition to that, limits the loss of wheat flour during the milling process as to prevent contamination to the outside air. The final products from this machine have al grades suitable for animal feeds and also fine flour for human consumption.

Wheat flour making machine uses a pneumatic roller mill and a high square sifter in making wheat flour. It also has an advanced impulse dust collector which ensures that the workshop is kept clean. This machine is easy to assemble and use. In addition to that, limits the loss of wheat flour during the milling process as to prevent contamination to the outside air. The final products from this machine have al grades suitable for animal feeds and also fine flour for human consumption. This machine has great benefits. It has a high yield in dergerming of wheat. This is because of the newly improved chamber that contributes to higher yield. The machine also has a lower operation and installation costs. It also consumes less power. Therefore, you do not have to worry about electricity bills when you have it. Its compact design lowers the need of low space. It also produces products of high quality and has a high milling rate.

This machine has great benefits. It has a high yield in dergerming of wheat. This is because of the newly improved chamber that contributes to higher yield. The machine also has a lower operation and installation costs. It also consumes less power. Therefore, you do not have to worry about electricity bills when you have it. Its compact design lowers the need of low space. It also produces products of high quality and has a high milling rate. Small scale wheat flour mill is a machine that is mainly for independent use and it can also be used in a small plant. This flour mill can be used to process various grains apart from wheat such as rice, maize and sorghum. The machine uses a pneumatic roller and has a great dust collector which is able to make sure that the workshop has remained clean throughout. This small scale mills are very easy to use because they come with a simple operation procedure. The machine has a compact structure with a good appearance. It also adopts a close sieve. This makes it have a succinct structure that is easy to change for sieve cloth and costs less.

Small scale wheat flour mill is a machine that is mainly for independent use and it can also be used in a small plant. This flour mill can be used to process various grains apart from wheat such as rice, maize and sorghum. The machine uses a pneumatic roller and has a great dust collector which is able to make sure that the workshop has remained clean throughout. This small scale mills are very easy to use because they come with a simple operation procedure. The machine has a compact structure with a good appearance. It also adopts a close sieve. This makes it have a succinct structure that is easy to change for sieve cloth and costs less.