The wheat flour mill United States industry has been characterized using a large volume of production. Most of the products that are manufactured usually have very low unit values, which make the economy of scale a necessity to minimize the average production costs. Most of the firms that wish to enter this market are going to need to produce wheat of the same scale so that they may be able to compete with the existing producers. Most of the scale economies are usually less critical for the firms that wish to create their higher valued products that are targeted to the niche markets.

Another thing you should know is that the level of the capital investment you will need to establish some of the industry operations may act as a hurdle to some of the new participants. You should also know that flour milling in the U.S is very capital intensive. You will be required to have your own large upfront investment for you to begin flour milling in U.S. You will be required to invest in the wheat processing machinery and plant. Flourmills usually provide different goods that are known to be diet staples. Therefore, this means that there is no need for you to worry about making a loss for this industry is going to remain relevant.

Author Archives: admin

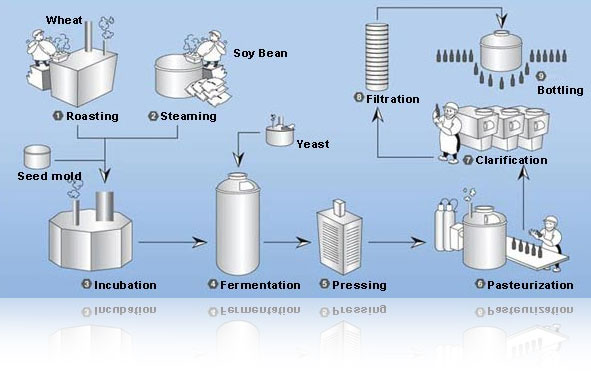

Wheat manufacturing process

Wheat manufacturing process involves a series of stages. The first stage involves grading of the wheat. In this stage, wheat is received at the flour mill where it is inspected. Samples of wheat are taken for both physical and chemical analysis. In this process, wheat is graded based on some factors but the most important factor is the protein content. The wheat is then kept into silos waiting to be milled. Before the wheat is milled, it has to undergo cleaning process. Wheat is passed through different cleaning processes to remove any foreign materials. The wheat and other small particles are passed through screens.

The wheat is then washed in warm water. Any foreign materials that remained during the cleaning process are removed in this stage. The next step involved in wheat manufacturing process is conditioning. In this process, the wheat is soaked in cold water for about 3 days or at a temperature of 46 degrees Celsius.

Wheat is then grinded where it also undergoes various processes. After that, the wheat is then processed into flour. During processing, small amounts of bleaching agents are added to the flour after milling. The flour is then packed into various bags.

Wheat flour production process

Wheat flour production process undergoes various stages. Immediately the wheat is brought into the flour mill, it undergoes quality control testing. The wheat is received and inspected. Samples are then taken for chemical and physical analysis. After that, the wheat is graded. Wheat is then kept in bags depending on its grade as it waits to be milled. Before the wheat is milled, it has to be cleaned first. This is because the wheat contains varius foreign materials that need to be removed. The wheat is passed through different screens to remove large and small particles. A magnet is also used to remove metallic substances that can be found in the wheat.

The wheat is then passed through an aspirator which is a device like a vacuum cleaner. The aspirator will suck up any foreign materials that are lighter than the wheat. The wheat is then washed in warm water and air dried. The next step involved in wheat flour production process is conditioning. In this process, the wheat is soaked in cold water for about 3 to 4 days or at a temperature of 46 degrees Celsius.

The wheat is then passed through an aspirator which is a device like a vacuum cleaner. The aspirator will suck up any foreign materials that are lighter than the wheat. The wheat is then washed in warm water and air dried. The next step involved in wheat flour production process is conditioning. In this process, the wheat is soaked in cold water for about 3 to 4 days or at a temperature of 46 degrees Celsius.

Wheat is then grinded where it also undergoes various processes. After that, the wheat is then processed into flour. During processing, 15 small amounts of bleaching agents are added to the flour after milling so that the flour can be decolorized. The flour is then packed into various bags and sold to retailers and consumers.

Wheat flour Processing

Wheat flour processing involves various stages. Before the wheat is processed, it must first have to be cleaned. Magnets are used to remove any metallic object, stones, and any other foreign materials that can be attracted by a magnet. Dust and chuffs in the wheat is removed by passing the wheat through air currents. There is an advanced color sorter being used today that separates impurities from the wheat by difference in color. This therefore reduces the product’s overall waste and improves the quality of flour.

Wheat flour processing involves various stages. Before the wheat is processed, it must first have to be cleaned. Magnets are used to remove any metallic object, stones, and any other foreign materials that can be attracted by a magnet. Dust and chuffs in the wheat is removed by passing the wheat through air currents. There is an advanced color sorter being used today that separates impurities from the wheat by difference in color. This therefore reduces the product’s overall waste and improves the quality of flour.

The next step involved in wheat flour processing is conditioning. This is done by dampening the wheat with water until it reaches a desired moisture content level. After that, the wheat is milled. This involves blending of different types of wheat to produce specific flour. The milling process is the one responsible in giving wheat a different and unique taste and characteristics.

The objective of the whole process is to extract as much endosperm as possible from the wheat. This is achieved by passing the already cleaned wheat in a series of rollers that rotates at different speeds. The broken particles of wheat are then separated by passing them through different sieves arrangement. The endosperm particles are then passed in a series of smooth rollers for the final milling process into flour. The flour can then be packed and sold to retailers and even cosumers

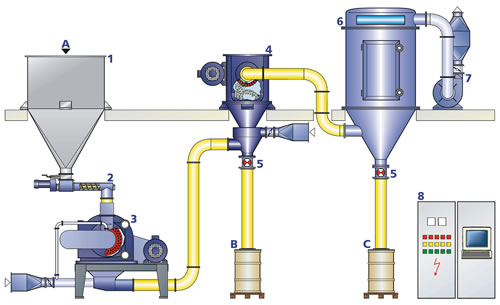

Wheat flour making machine

Wheat flour making machine uses a pneumatic roller mill and a high square sifter in making wheat flour. It also has an advanced impulse dust collector which ensures that the workshop is kept clean. This machine is easy to assemble and use. In addition to that, limits the loss of wheat flour during the milling process as to prevent contamination to the outside air. The final products from this machine have al grades suitable for animal feeds and also fine flour for human consumption.

Wheat flour making machine uses a pneumatic roller mill and a high square sifter in making wheat flour. It also has an advanced impulse dust collector which ensures that the workshop is kept clean. This machine is easy to assemble and use. In addition to that, limits the loss of wheat flour during the milling process as to prevent contamination to the outside air. The final products from this machine have al grades suitable for animal feeds and also fine flour for human consumption.

Manufacturer can design wheat flour making machine according to the customer’s request. The technicians in the companies have the skills of installing the machine and also train the local workers on smooth operation of the machine. Usually, this machine is perfect to use in small scale where input capacity is small. However, there are other models that can be utilized for medium and large scale but many people prefer the one for small scale.

This machine has great benefits. It has a high yield in dergerming of wheat. This is because of the newly improved chamber that contributes to higher yield. The machine also has a lower operation and installation costs. It also consumes less power. Therefore, you do not have to worry about electricity bills when you have it. Its compact design lowers the need of low space. It also produces products of high quality and has a high milling rate.

This machine has great benefits. It has a high yield in dergerming of wheat. This is because of the newly improved chamber that contributes to higher yield. The machine also has a lower operation and installation costs. It also consumes less power. Therefore, you do not have to worry about electricity bills when you have it. Its compact design lowers the need of low space. It also produces products of high quality and has a high milling rate.

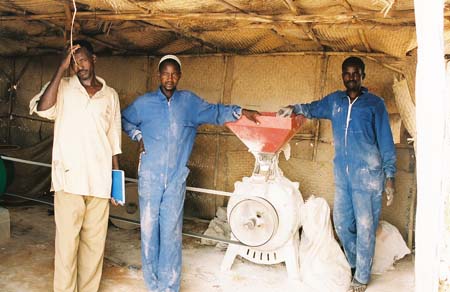

Small scale wheat flour mill

Small scale wheat flour mill is a machine that is mainly for independent use and it can also be used in a small plant. This flour mill can be used to process various grains apart from wheat such as rice, maize and sorghum. The machine uses a pneumatic roller and has a great dust collector which is able to make sure that the workshop has remained clean throughout. This small scale mills are very easy to use because they come with a simple operation procedure. The machine has a compact structure with a good appearance. It also adopts a close sieve. This makes it have a succinct structure that is easy to change for sieve cloth and costs less.

Small scale wheat flour mill is a machine that is mainly for independent use and it can also be used in a small plant. This flour mill can be used to process various grains apart from wheat such as rice, maize and sorghum. The machine uses a pneumatic roller and has a great dust collector which is able to make sure that the workshop has remained clean throughout. This small scale mills are very easy to use because they come with a simple operation procedure. The machine has a compact structure with a good appearance. It also adopts a close sieve. This makes it have a succinct structure that is easy to change for sieve cloth and costs less.

Small scale wheat flour mill has the advantage of producing low noise. It also consumes less energy. This is very effective to someone who is using the mill for business purpose as you will not have to spend a lot of money in producing wheat flour. Instead you will be one making maximum profits. The machine is highly efficient and has good performance. It’s also easy to maintain and has low operational costs. Moreover, it is stable during processing and has easy installation process.

It has a light weight that makes transportation easy. The machine comes with manual tripping which is linked with a flow control mechanical switches that brings reliable and sensitive operation while working

Flour milling machine corn grinder

The complete set of flour milling machine corn grinder has been developed based on the development of the international economy market. It has distinctive features. It has a long flour scheme, which adopts various systems such as break system, reduction system and scratch system. This is important for making the flour evenly and completely. This is what attributes to the high production of flour. The flower also becomes fine and presents a good color. Moreover, the gluten is also good and can make several sorts of flour.

Flour milling machine corn grinder has a simple design that makes its operation easy to handle. It operates on eco friendly procedures. This means, you do not have to call a professional to help you handle the machine when you have the procedure. All you need to do is read and understand carefully the procedure involved in handling the machine

The main technical parameters of the machine include an impressive output. The machine delivers an output of 50 tones per. The quality of the flour produced is of high quality. Its quality meets the stipulation of millers association. The machine uses a total of 167.95 KiloWatts of power. The power consumption per tone of corn is 60.65KW*h and uses 380V*50Hz. The advantages of this machine are that there is no ground hole, it can lift the wheat and receive bran and flour on the ground.

Wheat Flour Mill Angola Suppliers Increasing Your Profit Margin

Leading what growers know that the need for a reliable flour mill cannot be overstated. Having a reliable wheat flour mill will means that these companies are able to generate the required amounts output that will see to the steady increase of profit margins. Angola is one of the largest producers of what in the world. It’s entire economy is based on the agricultural sector and if you are looking to invest in this economy then you need the right machinery so that you can milk as much profits from the thriving economic sector. Wheat flour mill Angola supplies can help you do this.

Leading what growers know that the need for a reliable flour mill cannot be overstated. Having a reliable wheat flour mill will means that these companies are able to generate the required amounts output that will see to the steady increase of profit margins. Angola is one of the largest producers of what in the world. It’s entire economy is based on the agricultural sector and if you are looking to invest in this economy then you need the right machinery so that you can milk as much profits from the thriving economic sector. Wheat flour mill Angola supplies can help you do this.

They will supply you with the machinery to grind wheat harvested from your farms in Angola. The amount of what harvested from the farms will ensure determine the type of flour mills you invest in. But regardless of the size, you will be able to find the right machine to meet your needs. Wheat flour mill Angola suppliers can be found on the internet. From their websites you will find all the necessary information you need to know on the type of machinery you need for your farm. You do not need to be an investor in Angola to buy these mills. Wherever you run your mill production company, you can always take advantage of these superior mills.

They will supply you with the machinery to grind wheat harvested from your farms in Angola. The amount of what harvested from the farms will ensure determine the type of flour mills you invest in. But regardless of the size, you will be able to find the right machine to meet your needs. Wheat flour mill Angola suppliers can be found on the internet. From their websites you will find all the necessary information you need to know on the type of machinery you need for your farm. You do not need to be an investor in Angola to buy these mills. Wherever you run your mill production company, you can always take advantage of these superior mills.

Wheat Flour Mill Alibaba – Trusted Source for Mills

It’s hard to find a reliable supplier when you are in the market for a flour mill. Not so long ago, you had to go to a suppliers warehouse so that you can view as well as access different flour mills before making up your mind on the best flour mill for your needs. But this is history now. There is one website where you can find all the information you need on all types of flour mills and even other types of mills. The alibaba website is the internet trusted source when it comes to milling. The wheat flour mill alibaba website section will let you in on the various wheat flour mill, their reviews and even their prices. These are the biggest benefits you could ever hope to reap from a mill website.

It’s hard to find a reliable supplier when you are in the market for a flour mill. Not so long ago, you had to go to a suppliers warehouse so that you can view as well as access different flour mills before making up your mind on the best flour mill for your needs. But this is history now. There is one website where you can find all the information you need on all types of flour mills and even other types of mills. The alibaba website is the internet trusted source when it comes to milling. The wheat flour mill alibaba website section will let you in on the various wheat flour mill, their reviews and even their prices. These are the biggest benefits you could ever hope to reap from a mill website.

Whenever you are in the market for any appliance, machinery or products in general, then you have to read reviews. These reviews will give you first hand information on user experience, efficiency as well as expected delivery. The wheat mill alibaba website reviews section is no different. You will find consumer ratings, comparisons and conclusions on various wheat mills. From this, you can make a more informed decision when purchasing a wheat mill because:

OUR NEW WEBSITE HAS BEEN BUILT, IT HAS DETAILED CONTENT FOR WHEAT FLOUR MILLING AND THE MACHINES FOR THE WHOLE PROCESS, CLICK HERE FOR REFERENCE

Wheat Flour Mill Africa Suppliers

Agriculture in most developing countries is still at its infancy. The situation in Africa is quite the example for this point. Africa as a continent is blessed with fertile lands, round the year good climate and also man power that combined well with the aforementioned points should propel the continent to the top of the globe’s agricultural producers. But sadly this is not the point. The agricultural industry in Africa is yet to break off from its infancy. The lack of machinery, more precisely modern machinery, has been eating away at the continents potential. But with the entrance of wheat flour mill Africa suppliers, turnaround are soon to be expected.

Agriculture in most developing countries is still at its infancy. The situation in Africa is quite the example for this point. Africa as a continent is blessed with fertile lands, round the year good climate and also man power that combined well with the aforementioned points should propel the continent to the top of the globe’s agricultural producers. But sadly this is not the point. The agricultural industry in Africa is yet to break off from its infancy. The lack of machinery, more precisely modern machinery, has been eating away at the continents potential. But with the entrance of wheat flour mill Africa suppliers, turnaround are soon to be expected.

These suppliers are offering the continent the first chance to take their output and efficiency to the next level. It is through these suppliers that the available resources in the continent can actually be combined to give an unprecedented output. Wheat flour mill Africa suppliers have set up shop throughout the continent and also on the internet where they can easily be found. Projections on the output show that within two decades, famine can be eradicated from the continent. Surplus flour will then be exported to the rest of the world, improving the economic conditions of the whole continent. The future has never looked so bright for the continent.